MDF, MDHMR, ACP, WPC , Wood Cutting

MDF, MDHMR, ACP, WPC , Wood Cutting

MDF (Medium-Density Fiberboard), MDHMR (Medium Density High Moisture Resistance), ACP (Aluminum Composite Panel), WPC (Wood-Plastic Composite), and wood each require specific cutting techniques due to their different properties and compositions.

MDF Cutting:

- MDF is best cut with a saw equipped with a fine-toothed blade.

- Both table saws and handheld circular saws are suitable for cutting MDF.

- To minimize dust and achieve cleaner cuts, it's recommended to use a saw with a dust collection system.

MDHMR Cutting

- MDHMR, being a moisture-resistant variation of MDF, is cut using similar methods as MDF.

- It's crucial to use tools with sharp blades to prevent chipping or splintering.

ACP Cutting:

- ACP panels typically consist of an aluminum surface and a core material.

- For cutting the aluminum surface, a specialized panel saw with a non-ferrous metal cutting blade is recommended.

- To cut the core material, standard woodworking tools like a circular saw or jigsaw can be used.

WPC Cutting:

- WPC, being a composite of wood fibers and plastics, can be cut with woodworking tools.

- A saw with a fine-toothed blade designed for cutting plastics is suitable for WPC.

Wood Cutting

- Cutting wood requires various tools depending on the type of wood and the intended purpose.

- For solid wood, tools like handsaws, circular saws, and band saws are commonly used.

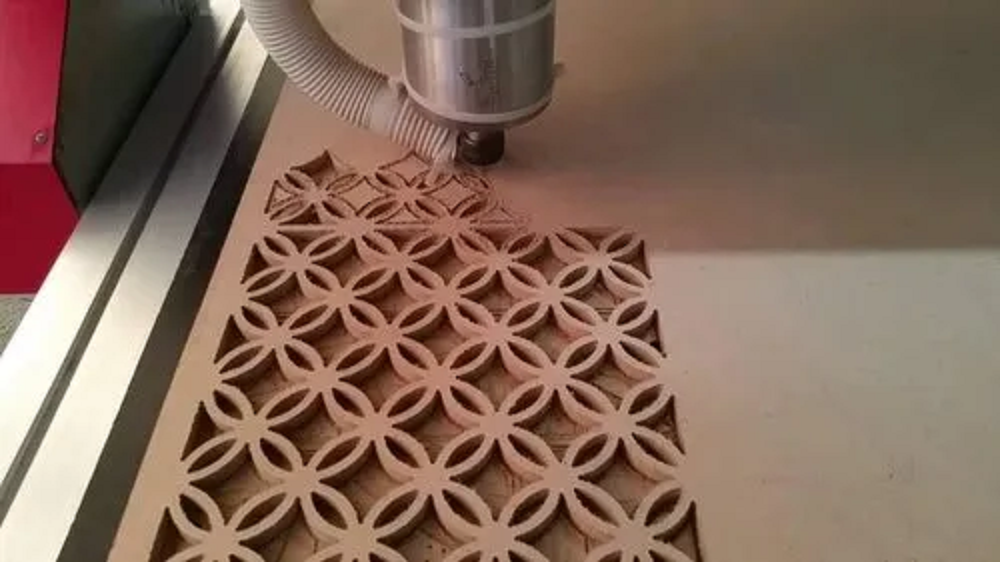

- To cut intricate patterns or curves, a jigsaw is a versatile choice.

- For precision cuts, a table saw is often employed.

Remember to wear appropriate safety gear like goggles, gloves, and a dust mask when cutting any of these materials. Additionally, ensure that you use the correct type of blade for the specific material you are cutting to achieve clean and precise results.